Building an AR 15 is not such a difficult task, especially when you have the best AR lower. That’s because lowers constitute as the base of the rifle. The lower is the region where the trigger mechanism and trigger are present. So all the more reason to buy one that you know ranks the highest in design and functionality!

Few people know what I’m about to tell you. The lower receiver of an AR rifle is the most significant part for another reason too. It’s the only piece of the firearm that displays the invaluable serial number.

So the lower is more than just a unique crafted chunk of metal. The receiver is the singular federally controlled component of the AR 15.

Time to find out more!

How to Choose the Best AR Lower Receiver?

Before I get to answering that question, here’s something you need to know about receivers. They are nothing but parts of the weapon that display the various serial numbers. This serial number comes in use for the federal license, so you can buy the firearm.

The primary task of the component is to assemble all parts associated with firing. These are present between the lower and upper receiver.

As a gun enthusiast, I’m sure you know that the receivers for AR 15 have a 2-piece design. The upper receiver houses the barrel and bolt. And its lower sibling carries the magazine and firing mechanism. Additionally, the lower also includes the useful serial number.

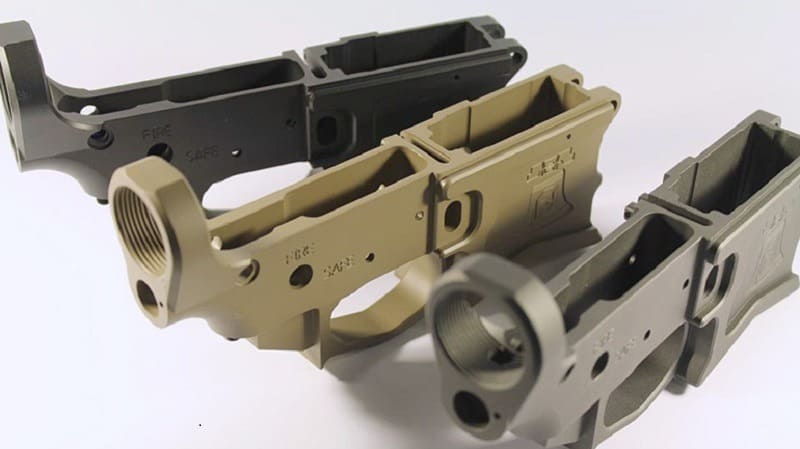

So in the following sections, I’m going to discuss the different types of best AR lower receivers. These either have a polymer or aluminum construction. On top of that, you get the opportunity to choose from three kinds of receiver styles. These include 80% assembled, forged, and billet.

What do you say, should we get started?

Best AR Lower: Receiver Style

· Billet

When compared to the other two, the billet is harder to work with. Making a billet style lower means putting in a lot of time and effort. And that’s the reason why it has such an expensive price tag, don’t you think?

Let me explain the process. The CNC-machined metal is carved using a singular billet block. This is how it takes the form of the lower receiver.

As far as strength goes, the billet version is not as strong as the forged design. Even so, it has the ability to withstand strong rifle recoils.

Additionally, making aesthetic changes is easier with this type of a lower receiver. As a result of which the whole experience becomes convenient.

· Forged

There’s no other style as common as the forged receiver. In this case, the hot, molded steel or aluminum is subjected to hammering. Such an action helps in achieving the shape and structure of the AR lower. Following which it is heat-treated to add more strength.

Soon after, the receiver undergoes several adjustments and modifications. These include engravings, coatings, smoothening, and drilling. Once the forging process is over, the result is an excellent quality lower receiver. One that delivers high strength.

No wonder the forged type is the most powerful of all three!

· 80% Assembled

Not completely assembled is what 80% assembled means. This is incredibly useful as you need no FFL license for buying such a lower receiver.

But you might have to use extra parts and tools to finish assembling the product. Technical skills are also necessary if you want to achieve precise results. For example, the process demands to add all kinds of different components. These include buffer tube threads, pinholes, and release cavity.

How To AR-15 Lower Receiver Build?

Best AR Lower: Construction Material

· Polymer

The best AR lower receivers with polymer design aren’t as powerful as the aluminum. But they are sturdier and more durable. The thing about polymer material is that it makes the manufacturing process easy. Also, it’s light in weight. So that’s another huge plus point!

As for withstanding recoil and abrasion, the polymer doesn’t let you down. It even has the capacity to resist strong impacts from heavy recoil.

Since this particular material is not as tough as aluminum, it is easier to carve and machine, right? For that reason, the majority of 80% assembled receiver types have polymer construction. So the process of assembling and modifying the remaining lower is a breeze.

· Aluminum

Most of the best AR lower receivers have an aluminum structure. And why is that? It’s because aluminum offers excellent corrosion resistance and high strength. Within this category, you get two options. These include 7075-T6 aluminum rating and 6061-T6 aluminum rating.

The latter delivers better tensile strength, which provides the greatest durability. As for the former, it has a lower price tag. This type of aluminum is easier when it comes to machining. And that’s because it is much less stress-resistant and strong. What such a characteristic translates into is minimal wear.

Cost of the Best AR Lower

As is evident, the cost primarily depends on the kind of receiver material and style. In the case of aluminum-designed billet-style AR lower, you might have to shell out extra bucks. But that’s not the deal with the forged versions. This only highlights the fact that billet styles need more time and effort. And that simplifies the manufacturing process.

Furthermore, the polymer material is cheaper than aluminum. And that’s because the latter is much more powerful than the former.

With that in mind, choose the style and type of material depending on your needs and requirements. The amount of money you’re willing to spend also plays a major role.

In all, remember that it’s always a better idea to buy a high-quality product. Otherwise, the performance factor gets compromised.

More Factors to Take Into Consideration

1. Quality Control

As a responsible buyer, it’s only common sense to buy products that rank the highest, quality-wise. But that doesn’t mean all manufacturers broadcast how phenomenal their equipment is. So at such times, what you can do is use your observation skills.

First, check the lower receiver’s pre-machined parts like the holes. These should have a proper alignment with a round shape.

The next component to take into account is the invaluable magazine well. Make sure that this particular element is well-machined. Thus, adhering to the dimensions of Mil-Spec. As a result of which the magazine receives a secure hold. And that, in turn, ensures a smooth release action.

2. Finishing

Standard finishing involves Type III anodized coating. Such a finishing provides optimal abrasion resistance. It also adds extra strength to the AR 15 lower receiver.

Products from renowned brands are subjected to sulfuric acid submersion. And for as long as two hours. Sometimes, even 10 minutes are more than enough. During this bath, electric currents are used. These create a layer of aluminum oxide on the surface of the receiver.

But that’s not the case with polymer constructed lowers. And that’s because the colors of these receivers are already built-in. Plus, polymer material contains certain natural properties. And these are not a part of aluminum.

Final Note

An AR rifle’s functionality and usability depend on its frame. The structure takes care of holding all the different parts together. Irrespective of the purpose of the weapon!

This means an excellent and reliable housing demands high-quality, sturdy structure. So it comes as no surprise to know that you should opt for well-constructed lower receivers. They are paramount to building a customized rifle.

You might also like: